A drop in well water pressure in winter can feel sudden, especially when showers, laundry, and dishwashers all need steady flow. Cold weather introduces a few predictable stress points in a private well system, from seasonal shifts in the water […]

Is your jet pump failing to deliver water as expected? Jet pump problems like cavitation or inadequate voltage can disrupt your water supply and cause frustration. This guide will provide step-by-step troubleshooting methods, repair techniques, and tips for maintaining your system. By addressing common issues and learning how to properly lubricate key components, readers will gain the skills needed to tackle jet pump failures effectively. Engaging with this content will empower readers to resolve their jet pump challenges and ensure a reliable power supply for their needs.

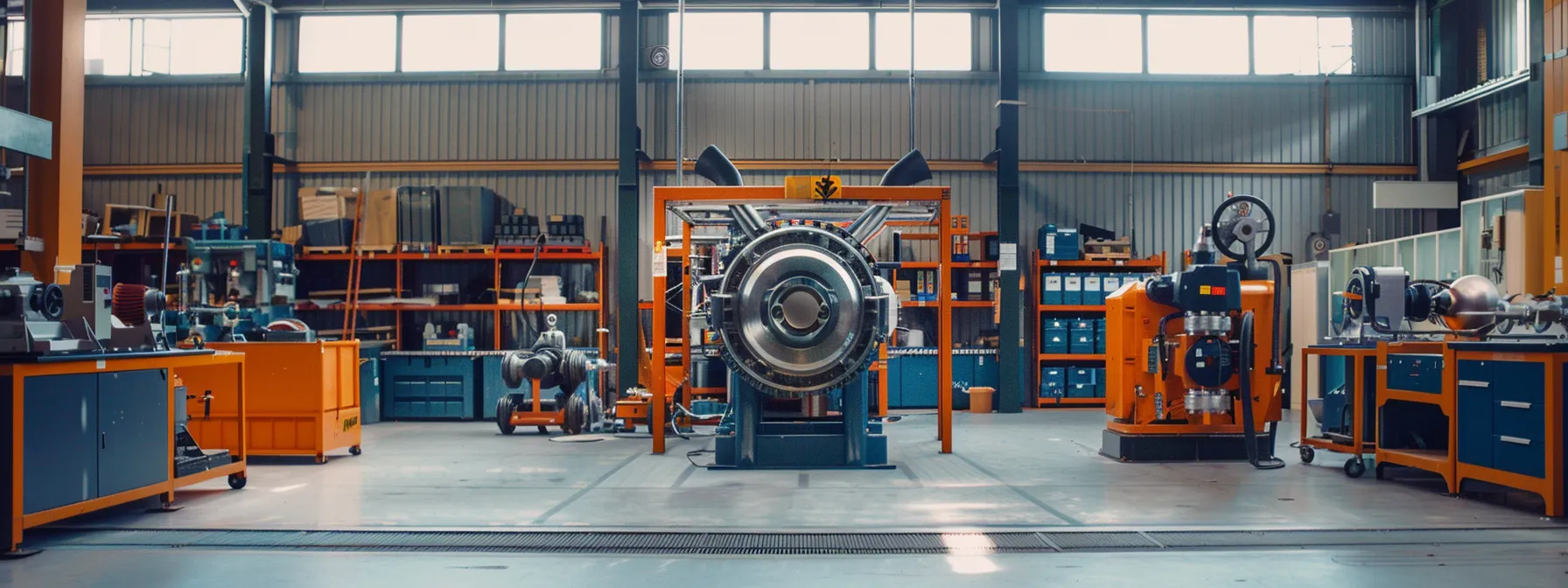

Jet pumps are essential components in various water systems, and understanding their operation can significantly aid in troubleshooting and repair. This section will explore how jet pumps work, including the roles of key components such as the impeller, wear on bearings, and friction points. Additionally, it will distinguish between shallow and deep well jet pumps, outline common applications, and emphasize the importance of routine maintenance to prolong pump life and efficiency.

Jet pumps operate by utilizing the principles of fluid dynamics to draw water from wells or other sources. The impeller generates high velocity in a confined area, creating a low-pressure zone that allows water to be lifted through the pipe and into the system. Proper functioning relies on components such as the air lock valve, which can impede flow if not maintained, and the electrical wire connections that power the pump, ensuring reliability and efficiency.

The key components of a jet pump play a critical role in ensuring the efficiency and reliability of the water supply system. Among these components, electrical wiring is essential for powering the pump, while the impeller generates the necessary pressure to lift water. Additionally, the bearings reduce friction, allowing the impeller to operate smoothly, which is vital for maintaining proper flow and minimizing wear and tear on parts. Regular maintenance, including checking screws and connections, can help prevent costly repairs and extend the warranty of the equipment:

Shallow well jet pumps are typically designed to lift water from depths of up to 25 feet, relying on atmospheric pressure to assist in drawing water into the system. In contrast, deep well jet pumps can extract water from depths exceeding 25 feet, employing a unique venturi mechanism and a bladder system to generate the necessary pressure for efficient operation. Understanding these distinctions is crucial for effective troubleshooting, as issues like a faulty gasket or an electrical short circuit can manifest differently depending on whether the pump is shallow or deep well, requiring targeted repair strategies to restore optimal performance.

Jet pumps serve a variety of essential functions across different applications, including providing water supply for residential use, irrigation systems, and aquaculture. In homes, they are commonly employed as a backup water source, especially in areas with inconsistent municipal water supplies, while also supporting features like hot tubs that require steady water pressure. Their adaptability allows for compatibility with multiple systems, such as compressors for irrigation, ensuring that users maintain optimal water flow regardless of the project’s diameter or complexity.

Routine maintenance for jet pumps is vital to ensure long-term functionality and reliability. Regularly inspecting and tightening screws with a wrench, checking the capacitor and circuit breaker, and monitoring the electric motor’s performance can prevent common issues such as clogging or electrical failure. For example, neglecting sewage buildup can lead to increased wear on the system, resulting in costly repairs and unnecessary downtime, emphasizing the need for consistent upkeep to maintain an efficient water delivery system.

Jet pumps can be reliable workhorses, but they aren’t without their troubles. Recognizing common issues will help keep them running smoothly and efficiently.

Identifying common jet pump issues is crucial for ensuring optimal performance. Recognizing symptoms of pump problems often involves observing low water pressure, which can stem from faulty components like a check valve or debris clogging the system. Detecting air leaks and troubleshooting electrical malfunctions, including examining the fuse and consulting a wiring diagram, are essential steps. Signs of mechanical wear can also indicate the need for timely repairs to maintain system efficiency.

Recognizing symptoms of pump problems is essential for maintaining the efficiency of a jet pump machine. Common indicators include low water pressure, which may signal a malfunctioning control valve or a leak in the system. Using a screwdriver to inspect connections and refer to the wiring diagram can help diagnose electrical issues, while checking for any visible leaks will aid in identifying potential points of failure that require immediate attention.

Low water pressure in a jet pump system can often be attributed to several factors that undermine its efficiency. Blockages in the pipes caused by sediment build-up or debris can restrict water flow, leading to inadequate pressure. Additionally, issues such as a malfunctioning check valve or worn-out bearings can also prevent the pump from generating the necessary force, potentially resulting in water flooding in locations like a basement, further compounding the problem and increasing energy usage in attempts to maintain pressure levels.

Detecting air leaks in a jet pump system is fundamental for maintaining efficient operation. A drop in electrical power, measured in volts, often indicates potential leaks, as the pump may struggle to maintain the necessary pressure. Additionally, operators should check for oil seepage around connections, which can signify wear and the need for replacement parts. Regular inspections promote reliability in systems that may include submersible pumps or even boiler applications where water pressure is critical.

Troubleshooting electrical malfunctions in a jet pump requires careful examination of several key components. Utilizing a voltmeter is essential for checking the electrical connections and ensuring that power is sufficiently reaching the pressure switch, which regulates the pump’s operation. If noise is detected during operation or if the pump fails to create suction, this may indicate issues such as a faulty capacitor that may need to be replaced, or connections that require tightening to restore optimal performance.

Signs of mechanical wear in a jet pump can significantly affect its performance and efficiency. Operators should look for indicators such as unusual noises during operation, which could suggest issues with the injector or bearings. Additionally, visible leaks around the pump or declining water pressure often signal the need for well water pump repair to prevent further damage and ensure reliable water supply.

Identifying the problems is only the beginning. Now, follow this troubleshooting guide to restore your pump's strength and ensure it runs smoothly once more.

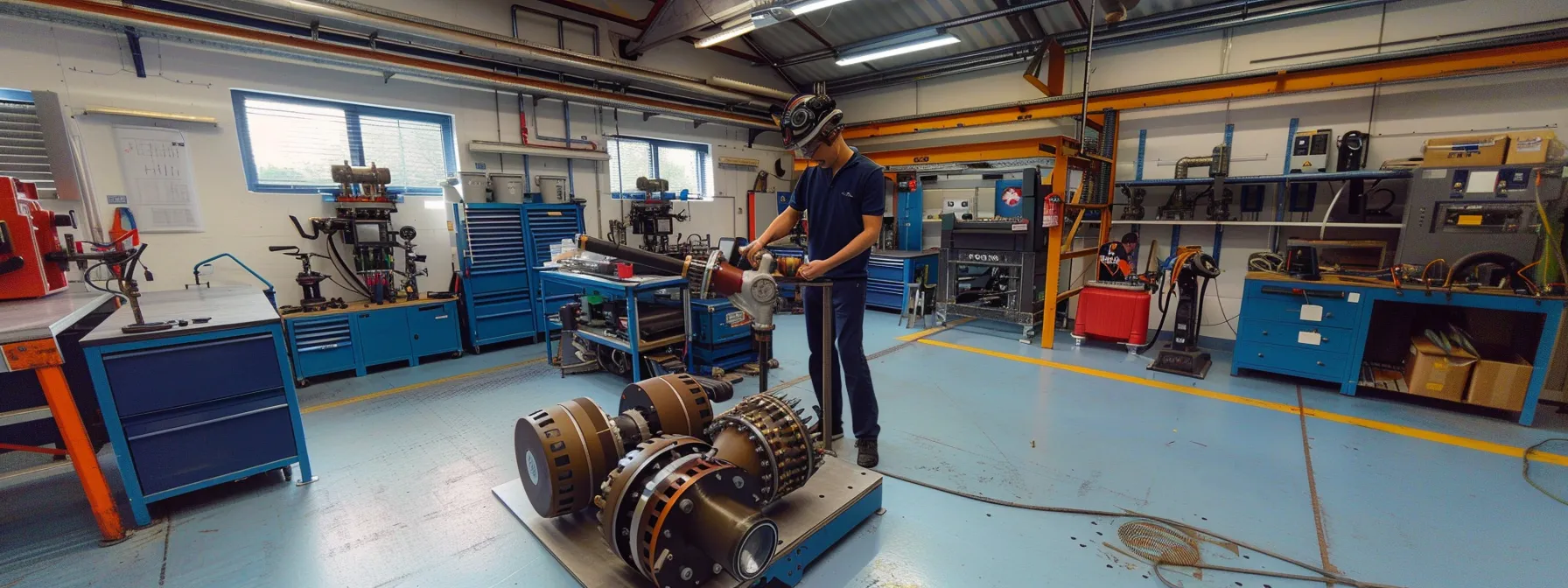

Before starting any troubleshooting process for jet pump problems, safety precautions are vital to ensure a safe working environment. This guide covers important areas to inspect, including assessing the pressure switch and settings, examining the pump impeller and diffuser, testing for suction line leaks, and evaluating electrical connections and components. Each section provides practical insights to facilitate effective repairs.

Before inspecting a jet pump, it is critical to take necessary safety precautions to ensure personal safety and prevent equipment damage. Individuals should first disconnect the power supply to the pump, avoiding electrical shocks while working on live circuits. Additionally, wearing appropriate personal protective equipment, such as gloves and safety glasses, is essential to safeguard against potential hazards such as sharp components or hazardous materials, particularly when addressing possible leaks or clogged parts:

Assessing the pressure switch and its settings is a vital step in troubleshooting jet pump issues. Operators must first examine the pressure switch for any signs of damage or wear, as a malfunctioning switch can lead to erratic pump operation or failure to start. Adjusting the pressure settings according to the manufacturer’s specifications ensures the pump operates efficiently, minimizing the risk of pressure fluctuations that could disrupt water supply.

Examining the pump impeller and diffuser is a critical step in troubleshooting jet pump problems. The impeller, which is responsible for generating the necessary pressure to lift water, should be checked for wear or damage, as any irregularities can significantly affect pump performance. Additionally, the diffuser plays a crucial role in directing water flow; ensuring it is free of obstructions is essential for maintaining optimal operational efficiency.

Testing for suction line leaks is an essential step in troubleshooting jet pump problems, as leaks can lead to decreased efficiency and increased operational issues. A simple way to identify potential leaks is by inspecting the suction line visually for any signs of wear or damage, such as cracks or loose connections. Alternatively, introducing a small amount of water or a leak detection solution along the suction line can help reveal air leaks through bubbling or the formation of air pockets, indicating where repairs may be needed:

Evaluating electrical connections and components is a fundamental process in troubleshooting jet pump issues. It is essential to carefully inspect each connection for signs of wear or corrosion, which can impede the flow of electricity and lead to malfunction. Additionally, using a multimeter to measure voltage and continuity helps ensure that the electrical components, including the motor and pressure switch, are operating correctly and efficiently, preventing unexpected failures and ensuring a reliable water supply.

With the troubleshooting steps completed, it's time to address the heart of the matter. Understanding how to repair jet pump problems will save both time and effort, ensuring reliable operation.

Repairing jet pump problems involves several critical steps to ensure efficient operation. This section will address key repairs, including replacing a faulty pressure switch, cleaning or replacing worn impellers, and sealing air leaks in pipes and fittings. Additionally, it will cover how to repair or replace electrical components and adjust pump settings for improved performance.

Each of these tasks plays a vital role in maintaining the pump's functionality, thus enhancing reliability and water supply efficiency.

Replacing a faulty pressure switch is a fundamental repair for ensuring the efficient operation of a jet pump. When the pressure switch malfunctions, it may prevent the pump from starting or lead to erratic operation, impacting water supply. To replace the switch, one must first disconnect the power supply for safety, then remove the old switch by unscrewing connections and replacing it with a new unit that matches the specifications of the system, ensuring proper calibration to maintain optimal performance.

Cleaning or replacing worn impellers is a critical step in maintaining the efficiency of jet pumps. Over time, impellers can accumulate debris or experience wear that reduces their ability to generate pressure, leading to decreased water flow. For optimal performance, operators should regularly inspect the impeller for signs of wear and promptly clean or replace it as necessary, ensuring that water systems operate smoothly and reliably.

Sealing air leaks in pipes and fittings is essential for maintaining the efficiency and effectiveness of jet pumps. When air enters the system, it disrupts water flow and can lead to decreased pressure and performance issues. Operators should carefully inspect all connections for signs of wear or damage and utilize appropriate sealants or replacement fittings to eliminate leaks, ultimately ensuring consistent pressure and reliable water delivery.

To effectively address issues with jet pump performance, repairing or replacing electrical parts is essential. Components such as the pressure switch or capacitor may degrade over time, affecting the pump's ability to start or maintain pressure. Technicians should ensure the power supply is disconnected before inspecting these parts, checking for any visible signs of wear or damage, and replacing them with compatible components to restore optimal functionality and system reliability.

Adjusting the pump settings is a crucial step in enhancing jet pump performance and ensuring efficient water delivery. Operators should consult the manufacturer's specifications to calibrate the pressure switch, as improper settings can lead to fluctuations in water pressure, resulting in reduced system reliability. By fine-tuning these parameters, users can optimize the operation of the pump, prevent potential overexertion, and extend the overall lifespan of the equipment.

Repairing jet pump problems takes skill and patience. To keep them running smoothly, understanding how to prevent future issues is essential.

Preventing future jet pump issues involves several proactive steps. Establishing a maintenance schedule ensures regular checks and upkeep, while best practices for installation promote long-term functionality. Monitoring system performance regularly can identify minor problems before they escalate. Additionally, protecting the pump from environmental damage preserves its efficiency, and knowing when to consult a professional can save time and resources in repairs.

Establishing a maintenance schedule for jet pumps is essential for preventing operational issues and ensuring longevity. Regular inspections, such as checking for leaks, monitoring pressure levels, and tightening electrical connections, can identify problems before they escalate into costly repairs. By committing to a routine maintenance plan, users can enhance the reliability of their water systems and avoid unexpected breakdowns that disrupt water supply and efficiency.

Effective installation practices are critical for the longevity and reliability of jet pumps. Proper placement of the pump, with attention to aligning the inlet and outlet pipes, directly influences the pump's ability to function efficiently. Additionally, ensuring that all connections are securely tightened and using appropriate sealants to prevent leaks significantly reduces the risk of future complications:

Regular monitoring of jet pump performance is essential for identifying potential issues before they become significant problems. By consistently checking water pressure, power consumption, and overall system responsiveness, operators can detect deviations that may indicate wear or malfunction. For instance, maintaining an eye on any changes in water flow can provide early signs of clogs or leaks, allowing for timely interventions that preserve pump efficiency and functionality:

To protect a jet pump from environmental damage, it is essential to secure the pump in a sheltered location, away from harsh weather conditions such as rain, snow, and direct sunlight. Using protective housing or covers can help shield the components from debris and moisture, preventing rust and corrosion that could impair functionality. Additionally, ensuring proper drainage around the pump installation site minimizes the risk of flooding during heavy rains, further safeguarding the system and enhancing its lifespan.

Knowing when to consult a professional for jet pump issues is vital for ensuring the system operates effectively. If the troubleshooting procedures do not resolve the problem, or if there are complex electrical issues or persistent leaks, it may indicate underlying defects that require expert intervention. Engaging a qualified technician can not only prevent further damage but also provide insights into advanced maintenance practices to prolong the pump's lifespan:

Sometimes, even the best systems wear out. Upgrading or replacing your jet pump could be the next step toward a more efficient and reliable solution.

Deciding whether to repair or replace a jet pump is a critical choice that requires careful consideration of needs and resources. This section provides insights into selecting the right jet pump suited for specific applications, offers essential installation tips for new systems, and outlines budgeting considerations for upgrades. Additionally, it emphasizes the importance of finding reliable parts and support to ensure a successful transition.

When faced with jet pump issues, determining whether to repair or replace the system can be challenging. If frequent repairs have become necessary or the pump no longer meets specific water demand requirements, replacement may be the more cost-effective solution in the long run. Evaluating performance history alongside the age of the pump can help operators decide; typically, a pump older than ten years might benefit from an upgrade, especially if modern models provide improved efficiency and reliability.

Selecting the right jet pump for specific needs involves assessing several key factors, including the depth of the water source, desired flow rate, and intended applications. For instance, a shallow well jet pump is suitable for depths up to 25 feet, while deeper applications require a deep well jet pump with enhanced pressure capabilities. Understanding these parameters can help operators choose a jet pump that optimally meets their requirements, ensuring efficient and reliable water delivery:

When installing a new jet pump, it is essential to ensure that it is positioned correctly and securely to facilitate optimal operation. The pump should be placed in a location that provides easy access for maintenance and is equipped with adequate drainage to prevent flooding. Furthermore, aligning the inlet and outlet pipes accurately during installation will minimize stress on the fittings and enhance the overall long-term functionality of the system.

Budgeting for upgrades and replacements of jet pump systems involves careful planning to ensure financial feasibility while meeting water supply needs. Operators should consider the costs associated with purchasing new pumps, installation expenses, and potential ongoing maintenance. It is essential to compare the performance of different models, factoring in efficiency ratings, to make an informed financial decision that balances initial investment with long-term savings on energy and repairs.

Finding reliable parts and support for jet pumps is crucial for ensuring longevity and optimal performance. Operators should prioritize purchasing components from reputable suppliers or manufacturers to ensure compatibility and quality. Additionally, seeking technical support from experts can provide valuable insights on installation and maintenance, ultimately preventing future issues that may arise during operation:

The "Complete Guide to Troubleshooting and Repairing Jet Pump Problems" highlights the critical role of regular maintenance and prompt repair in ensuring the efficiency and longevity of jet pumps. Understanding key components and troubleshooting techniques empowers users to address common issues effectively, reducing downtime and maintenance costs. By establishing a proactive maintenance schedule and knowing when to seek professional assistance, operators can significantly enhance system reliability and performance. This comprehensive approach not only preserves the functionality of water supply systems but also maximizes their operational efficiency, underscoring the importance of informed management of jet pump systems.

A drop in well water pressure in winter can feel sudden, especially when showers, laundry, and dishwashers all need steady flow. Cold weather introduces a few predictable stress points in a private well system, from seasonal shifts in the water […]

When winter temperatures drop, Northern Virginia homeowners often focus on keeping their homes warm, but freezing weather can pose serious risks to private well systems [1] if proper precautions aren’t taken. Even in regions that don’t typically experience harsh winters, […]

A home with a private well depends on more than just turning on the faucet. Behind the steady flow of water is a system working every day to pump, store, and deliver what your household needs. While it often runs […]